Airless pump bottles wholesale biodegradable PCR 15ml 30ml 50ml lotion airless bottles-AS-016

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, top quality

150ml airless bottle 4oz airless pump bottle empty plastic container biodegradable PCR-AS-112

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, top quality

Square airless bottle twist up airless cosmetic container-AS-086

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, refillable

Airless pump bottles matte silver airless pump frosted bottles cosmetic-AS-024

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, refillable

2 in 1 cosmetics airless bottle 15g x2 tube day night cream dispenser bottle-AS-108

Press up-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, top quality

Airless pump spray bottle airless spray perfume bottles-AS-047

Fine mist spray airless packaging is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, top quality

Matte airless dispenser bottle 15ml 20ml massage pump eye cream bottle-AS-106

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, refillable

Gold airless pump bottle 10ml 15ml 20ml 30ml reuse airless pump bottle-AS-105

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, refillable

Airless bottles for skin care 15ml 30ml 50ml black airless pump spray bottle-AS-032

Press-type airless sub-bottling is essential for travel and convenience at home.

Our airless pumps: no leak, good sealing, refillable

Kraft paper deodorant tubes 50g eco paper kraft lip balm tubes

Product: Paper deodorant stick container

Apply for deodorant, antiperspirant, lip balm, foundation stick, lipstick. It is biodegradable and oil-proof.

Volume:Customized

Color: welcome to custom

It is printable

Good quality kraft paper with certified. Welcome to custom your mold.

AS-069-acrylic airless dispenser bottles 15ml-30ml-50ml

Product: 15ml-30ml-50ml-airless bottle for cosmetics, airless cream bottle, airless dispenser bottle, airless bottle pump

Acrylic bottle Looks luxury

Color is changeable

Silkscreen printing is availableT-002-alumnium laminated tube cosmetic soft tube with octagonal cap PE plastic tube 50g PCR laminate tube

Features:

1, We manufacture cosmetic tubes with mono-layer, five-layer(Multiple-unit tube with EVOH bonding layer), Two-layer, Double layer,Oval Shape , Flat Shape and Round shape.

2, Capacity: 3ml- 550ml

3, Diameter: 13-60mm

4, Application: Food, Cosmetics, Pharmaceutical etc.AP-013-disposable eye serum bottle 3ml-5ml

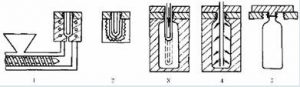

Product:plastic ampule bottle,plastic ampoule bottle, push up eye cream bottle, disposable plastic bottle, airless bottle tube, small needle bottle for eye cream, eye serum and eye essences.

Capacity: 3ml,5ml

Bottle body is PP material, non-toxic.

Filling from the bottom before sealing the rubber, and break the tip when using.

Color is changeable

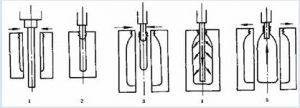

Silkscreen printing is availableJH-AS-049-Small ampule bottles, ampule dropper bottles 1ml,5ml,10ml

Product: Small ampule bottle, plastic ampule bottle 1ml, 2ml, 3ml,4ml,5ml,10ml.

Apply for cosmetics, body care, skin care, personal care, and face care.

We manufacture those ampule bottles for high quality cosmetics, serum and lotion.

It is disposable packaging.We also stock many ampule bottles, you can order at small amount quantity.

JH-AS-058-15g-30g-50g twist up airless dispenser bottle

Twist up airless bottle 15g,30g,50g

DP-004-round deodorant stick tube 80g

It is a good choice for deodorant products.

Various colors are available.

One time useage, wonot be leak,Good PP plastic quality.AS-022-airless press pump bottles airless dispenser jar15g-30g-50g

Product: pearl airless dispenser bottle, airless pump bottles for cosmetics. 15g-30g-50g

This airless pumps cannot be refilled when finish the inner products.

Color is changeableCanvard team firmly believes that we can do the best and provide worry-free product quality and service to global customers. High-quality product quality, considerate team service and direct factory prices are deeply loved by customers around the world. Customers from all countries in the world are welcome to buy our packaging products.

AS-021-airless pump bottle for face cream

Product:airless pump bottle for face serum, Clear ABS bottle with aluminum cover to demonstrate the luxury.

Volume: 15ml-30ml-50ml-100ml

Color:changeable

Printing:silkscreen printing, hotstamping

SO-001-foam pump bottles 100ml-120ml-200ml-250ml 100% PCR material

Advantages of foam pump bottle

Our foaming pump bottles are strong and contains no dangerous chemicals or compounds.It is made of BPA free plastic, durable and recyclable. These are drop resistant and durable for long term use.Widely use for soaps, shower gels, hair mousse, liquid hand soap, children’s shampoo, skin care item, facial cleansers etc.

We benefit our clients with Production Flexibility, Manufacturing Efficiency, Quality Guarantee and Competitive Price.

Located in Guangzhou, our production base covers an area of over 20,000 square meters, integrating R&D, OEM manufacturing, and packaging. Our strengths include:

· 10+ automated production lines

· Strong production capacity:

12 million bottles, 30 million caps&closures and billions of foil seals per month

· Strict quality control with ISO 9001, SGS, MSDS certification

Canvard team earns a great reputation from the the world, is more worry-free and responsible, and is conscientious and careful in the process of order documentation, so that customers can enjoy high-quality services in the entire procurement process of pre-sale, in-sale and after-sale. Our team firmly believes that we can do the best and provide worry-free product quality and service to global customers. High-quality product quality, considerate team service and direct factory prices are deeply loved by customers around the world. Customers from all countries in the world are welcome to buy our packaging products.We are the best!

Spirit of the Canvard Team: aggressive, efficient and pragmatic.