How to Choose the Right PE Cosmetic Soft Tube

How to Choose the Right PE Cosmetic Soft Tube

Cosmetic tubes, including those made from Polyethylene (PE), have revolutionized packaging in the cosmetics and pharmaceutical industries. Known for their hygiene, convenience, vibrant surface colors, and economic advantages, PE tubes maintain an excellent appearance even after intense squeezing. They are widely used for packaging paste-like cosmetic products such as facial cleansers, conditioners, hair dyes, toothpaste, and topical ointments in the medical sector.

1, Material and Type Classification of Cosmetic Tubes

Cosmetic tubes generally comprise the tube itself plus a cap, with the tubes frequently made from PE plastic. Alternatives include laminated (aluminum plastic) tubes, all-aluminum tubes, and eco-friendly paper plastic tubes.

All-Plastic Tubes

: Entirely made from PE, these tubes are extruded, cut, and then printed with various techniques like ink printing, silk screening, and hot stamping. They can be categorized by the shape of the tube head (round, flat, oval) and the type of seal (straight, diagonal, custom shapes).

Laminated Tubes

: Featuring an inner layer of PE and an outer layer of aluminum, these tubes are cut and then rolled. Options for the tube head and seal are similar to those of all-plastic tubes.

- \

All-Aluminum Tubes

: Made entirely from recyclable aluminum, offering an eco-friendly choice. Their downside is susceptibility to deformation, making them ideal for high-end product packaging where cosmetic appearance is paramount.

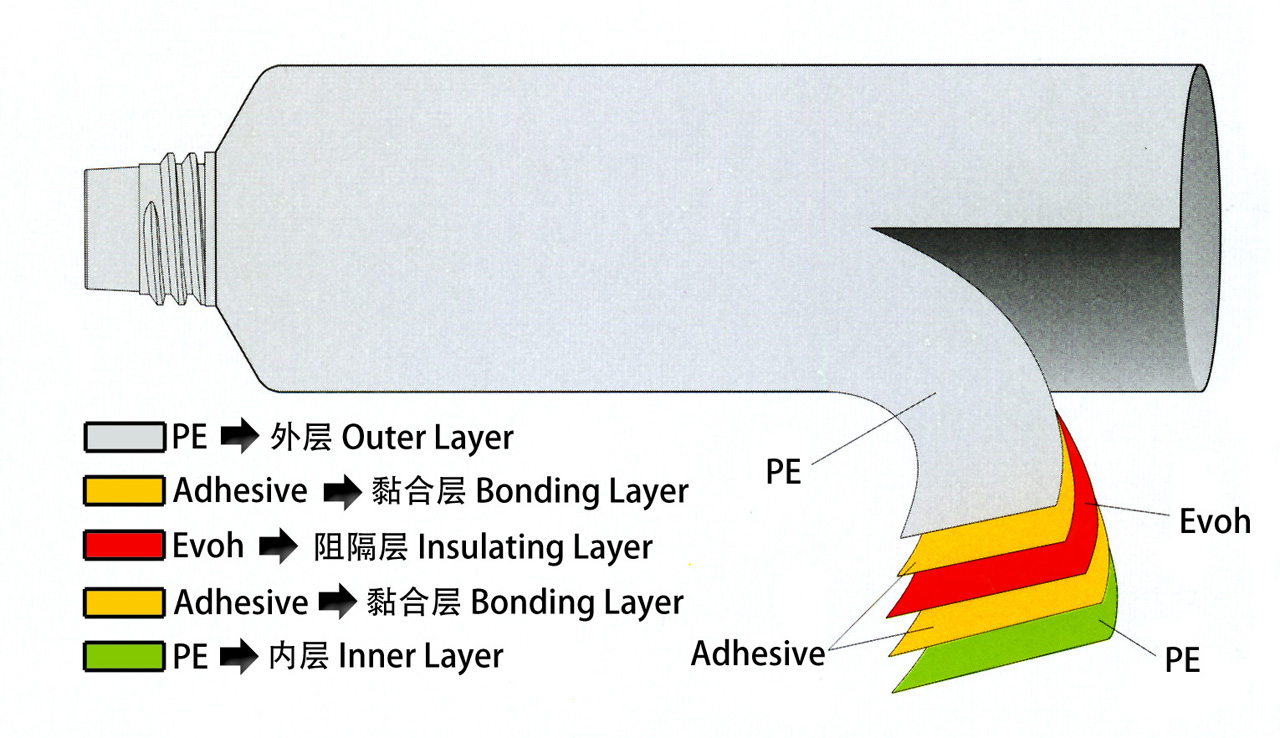

2, Classification by Product Thickness

Tubes can be single-layer, double-layer, or five-layer, offering varying degrees of pressure resistance, permeation prevention, and tactile feel. Single-layer tubes are thinner, double-layer tubes are more common, and five-layer tubes are premium, featuring an outer layer, inner layer, two adhesive layers, and a barrier layer for exceptional gas barrier properties.

3, Tube Shapes

Available shapes include round, oval, flat, and super flat, catering to different aesthetic and functional requirements.

4, Tube Diameter and Height

Tube diameters range from 13# to 60#, with different lengths indicating capacity from 3ml to 360ml. For visual harmony, tubes under 60ml typically use diameters under 35#, while those for 100ml and 150ml use 35# to 45#, and larger capacities require diameters above 45#.

5, Tube Caps

Caps vary widely, including flat, round, tall, flip-top, super flat, double-layer, spherical, and lipstick caps, with options for decorative processes like gold or silver edging, colored caps, transparency, spray oil, and electroplating. Pointed and lipstick caps usually come with an inner plug.

6, Manufacturing Process

Tube Body

: Options include colored, transparent, matte or glossy finishes, with matte appearing elegant but prone to dirt. Tube colors can be directly integrated into the plastic or achieved through extensive printing, distinguishable by the color at the cut end of the tube. High-quality ink is necessary to prevent peeling and cracking under stress.

Printing

: Techniques include silk screening (for specific colors and small blocks, similar to plastic bottle printing) and ink printing (for larger, more colorful designs, commonly used in daily chemical lines), along with options for gold and silver hot stamping.

7, Specific Tube Production Process

The manufacturing of cosmetic tubes involves a sequence of precise and specialized steps to ensure product quality, functionality, and appearance. Here’s an overview of the typical production process for cosmetic tubes:

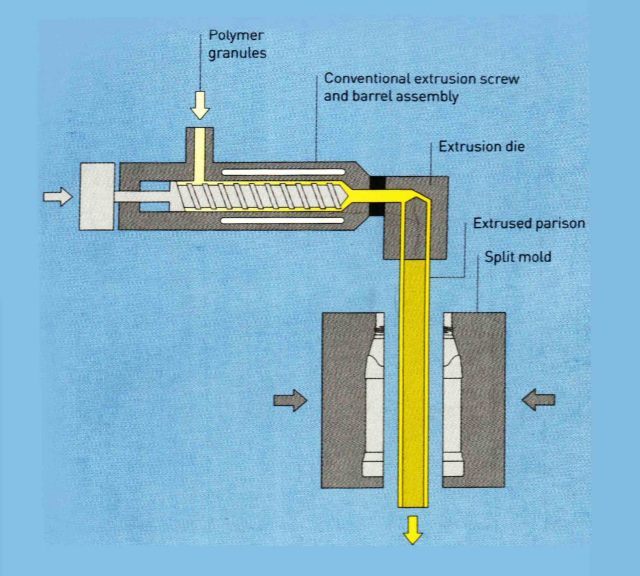

Tube Extrusion

: The process begins with extruding the tube material, typically polyethylene (PE) or a combination of materials for laminated tubes, into the desired shape and length.

Ink Printing (Offset Printing)

: This step involves applying colored designs, logos, and text onto the tubes using offset printing techniques, which allows for high-quality, detailed images.

Silk Screening

: An additional method for applying graphics to the tube, silk screening is used for vibrant, opaque colors and can apply thicker layers of ink than offset printing.

Hot Stamping (Foil Stamping)

: A decorative process that applies metallic or pigmented foil onto the tube for a shiny, reflective effect. It’s commonly used for logos, accents, or text to add a premium look.

Labeling

: Applying labels to the tube, either by wrapping pre-printed labels around it or by directly adhering them to the tube surface. Labels can provide additional information, branding, or decoration.

Nozzle Insertion

: Attaching the nozzle or applicator to the tube, which can vary in design based on the product’s application method (e.g., narrow tip for precision or wider openings for thicker creams).

Capping

: Screwing or pressing the cap onto the tube. Caps can vary widely in design, from simple screw caps to flip-top, twist-off, or pump-action caps, depending on the product requirements.

Packaging

: The final step involves packaging the finished tubes for shipping and retail. This can include placing tubes into boxes, sealing, and labeling the packages for distribution.

And compared to most other types of packaging, airless packs have a high restitution rate—waste is avoided, as nearly all of the formula is used.

And compared to most other types of packaging, airless packs have a high restitution rate—waste is avoided, as nearly all of the formula is used. When we need to use it, a gentle pump dispenses the desired skincare product. This airless bottle is suitable for lotions, serums, liquid foundations, eye creams, and other skincare products that are not excessively viscous or too fluid.

When we need to use it, a gentle pump dispenses the desired skincare product. This airless bottle is suitable for lotions, serums, liquid foundations, eye creams, and other skincare products that are not excessively viscous or too fluid. The small hole at the bottom of the bottle allows for adjustable positioning of the vacuum piston to meet different capacity needs.

The small hole at the bottom of the bottle allows for adjustable positioning of the vacuum piston to meet different capacity needs.

Ⅰ. Product description:

Ⅰ. Product description: