Portable induction sealing machine bottle cap sealer 20-100mm

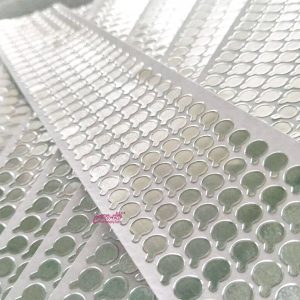

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproof

Seal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

- Description

- Factory&Packing

- Certificate

- Video

- Inquiry

Portable induction sealing machine

Portable induction sealing machine

Features:

1. Self-counting function to effectively control the number of seals.

2. The structure of the design is reasonable, and the touch panel operation is convenient and simple.

3. Automatic pressurization, heating and overcurrent protection functions.

4. Ultra-wide voltage application range.

5. The product has stable performance and long service life.

Technical parameters:

| Power supply: | AC220V+_10% |

| Power: | <1.2KW (adjustable) |

| Current output | Static<2A; Dynamic<10A |

| Maximum allowable power supply current: | <10A |

| Operating frequency: | 50-80Hz (+-5%) |

| Sealing diameter: | 20-100mm |

| Dimension: | 34x29x15cm |

| Working environment: | 0-40degree clean/dry |

| Sealing material | non metallic packaging |

| Overall Weight: | 5kg |

Warm tip: Seal plastic, glass and other non-metallic bottles by induction heating. Do not seal metal bottles or bottles with metal caps.

Related Products

Read MoreQuick View

Read MoreQuick ViewPrintable inductive aluminium foil seal pressive glass bottle jar seal foil

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewPressure sensitive foam seal self adhesive bottle lid gasket

• Pressure-sensitive seal liner is a single-piece adhesive gasket, which is non-toxic, odorless, strong sealing, good chemical performance.

• Material: PS foam of coated with pressure sensitive adhesive.

• Thickness: 0.6mm/ 0.8mm/ 1.0mm/ 1.2mm/ 1.5mm/ 2.0mm

• How to use: No need machine to seal.

- Put the pressure-sensitive seal liner on the plastic lid;

- Tighten the bottle cap.

Read MoreQuick View

Read MoreQuick ViewSilver aluminum foil sealing glass plastic jar aluminum foil gasket

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewPET foil seal aluminum foil seal sealing foil for bottles 1.2cm

Why use aluminum foil seal for tube?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofAdhesive seal foil is widely used in bottle, jar, tube

Read MoreQuick View

Read MoreQuick ViewSingle layer inductive aluminium foil seal pressive glass bottle jar seal foil

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewPressure sensitive foil sea pad aluminum seal foil

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewAluminum foil lid seal heat induction lid liner

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewPressure sensitive foam gasket adhesive sealed for your protection

• Pressure-sensitive seal liner is a single-piece adhesive gasket, which is non-toxic, odorless, strong sealing, good chemical performance.

• Material: PS foam of coated with pressure sensitive adhesive.

• Thickness: 0.6mm/ 0.8mm/ 1.0mm/ 1.2mm/ 1.5mm/ 2.0mm

• How to use: No need machine to seal.

- Put the pressure-sensitive seal liner on the plastic lid;

- Tighten the bottle cap.

Read MoreQuick View

Read MoreQuick ViewInduction sealing PET PE bottle aluminum foil lid liner

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewSeal alumininum foil sealing foil for bottles

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewSeal aluminium lid film heat seal foil seals jar

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewEasy tear off inductive sensitive aluminium foil seal pad peelable seal foil gasket

• Aluminum foil PE foam seal liner is easy to use, good sealing, anti oxidation. Theftproof, Anti leakage.

• Material: Composed of sealing layer, aluminum foil, adhesive glue layer, PE foam

• Thickness: 0.6mm-2.0mm

• How to seal: Heat induction/ Electromagnetic induction

Read MoreQuick View

Read MoreQuick ViewPTP aluminum foil seal for food and medicine seal foil flim

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakageGood tightness, oxidation and moisture resistance, welcome to order

Read MoreQuick View

Read MoreQuick ViewTempplate pierceable sealing foil microplate aluminum foil seal

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewAluminum foil lid seal micro biology tube lid foil seal liner

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewAirtight waterproof pressure sensitive aluminium seal foil

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewLaminated foil bottle seal induction lid liner yogurt capsule seal

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewSelf adhesive pressure sensitive foil seal bottle cap plastic film gasket

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewBottle sealing foil heat seal aluminium lids

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.

Read MoreQuick View

Read MoreQuick ViewHot melt glue adhesive pressive seal gasket inductive aluminium foil seal

Why use aluminum foil seal?

Block the product inside the container from direct contact with the outside air. It can keep the quality of the product unchanged for a long time, and alleviate the bottleneck chipping caused by handling or transportation.

The advantages of foil seal gaskets: dustproof, waterproof,anti-breakage,moistureproofSeal foil is widely used in PET, PE, PP, PVC, PS, ABS and glass bottles containers.