What Manufacturing Process are Shampoo Bottles Dade by

What manufacturing process are shampoo bottles made by

Everyone uses shampoo, but most people may only pay attention to the shampoo products. However, some of them may also keep an eye on the plastic container holding the shampoo. They may wonder what the manufacturing process of plastic containers is. In this article, you can better understand the plastic container holding the shampoo and its manufacturing process.

Everyone uses shampoo, but most people may only pay attention to the shampoo products. However, some of them may also keep an eye on the plastic container holding the shampoo. They may wonder what the manufacturing process of plastic containers is. In this article, you can better understand the plastic container holding the shampoo and its manufacturing process.

PET bottle

PET material is safe, has no plasticizer, and is sufficiently flexible, with a high transparency grade. Many colors are available for PET bottles, like transparent, semi-transparent, and solid colors. Some brands prefer the PET bottle to be strong and hard to squeeze, while some products need to be squeezable, such as hair conditioners. How is PET material a safe material? You can see many drinking bottles using PET material; it is good evidence. But PET material cannot be put into a high-temperature container; its heat-resistant temperature is about 70℃, so PET bottles can only be stored at room temperature or cold beverages. For shampoo, there is no worry to use PET bottle at all.

PE bottle

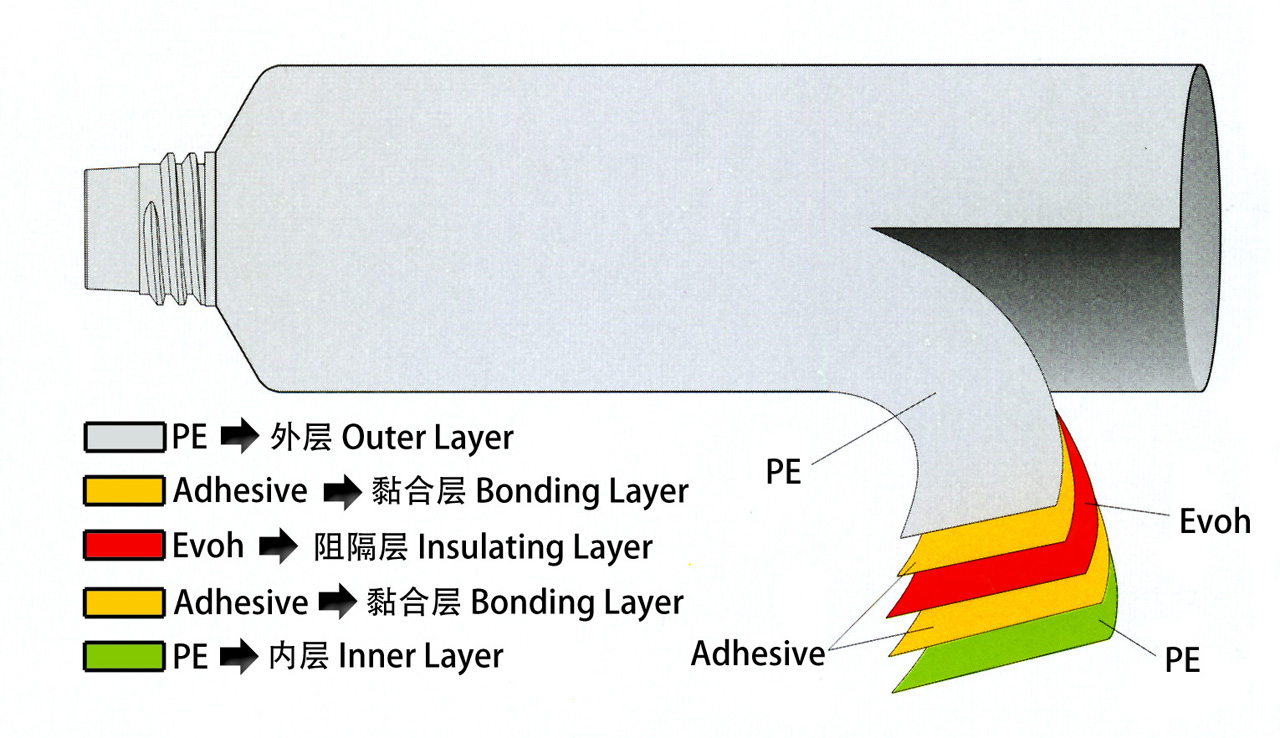

PE plastic is one of the most commonly used materials for shampoo; its natural color is opaque and can hold some large-capacity shampoo products. Therefore, PE bottles can resist the erosion of many chemical products; they are widely used for storing cosmetics, detergents, and more. Moreover, PE bottles are cheaper than PET bottles and incompatible with plasticizers. It can also be used as a material for food preservation, so it is non-toxic.

PP bottle

PP material is milky white and translucent, which looks like the milky white of body milk, not pure white or transparent.PP bottles are soft and squeezable, but the transparency is not as good as PET bottles, so some opaque shampoo bottles also prefer to use PP bottles, such as hair dye products and hydrogen peroxides. For colored PP bottles, it is made by adding a color master, which means adding the color master in mixing material. PP plastic products are safe and non-toxic, too, and there is no plasticizer.

The above paragraphs have explained the three main plastic materials for shampoo bottles: PET, PP, and PP. The following is the manufacturing process of these three types of plastic materials.

The manufacturing process of PET bottles and PP bottles typically have two methods:

one is a step process, and the other is a two-step process. Now, many PET bottles are produced by a two-step process: Use the injection machine to cast a preform(like a tube), then put this bottle preform into a bottle blowing mold, blow it to match the bottle mold perfectly, and the preform tube will be expanded into the mold shape, take it off and make it cool down.

The ingredients of shampoo are mainly used for increasing the glossiness of hair and to sterilize, clean, and foam, which will not be harmful to PE bottles, and PE material is not soluble in water, with low water absorption, it is very safe to use PE bottle too.

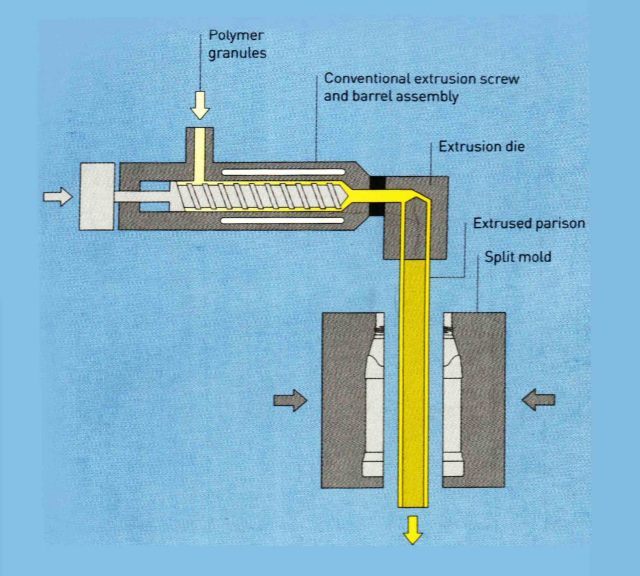

PE bottles are usually manufactured by hollow extrusion blow molding process, which is to melt and plasticize the PE material by the extruder, extrude the tubular parison, and then place the parison in the blow molding mold, blow it with compressed air, and cool the PE bottle of the exact shape of the mold obtained.