What are the different methods of extrusion blow molding?

What are the different methods of extrusion blow molding?

What are their advantages and disadvantages?

Based on the different ways of discharging in extrusion blow molding, it can be divided into two molding processes: direct extrusion blow molding and extrusion-storage-pressure blow molding.

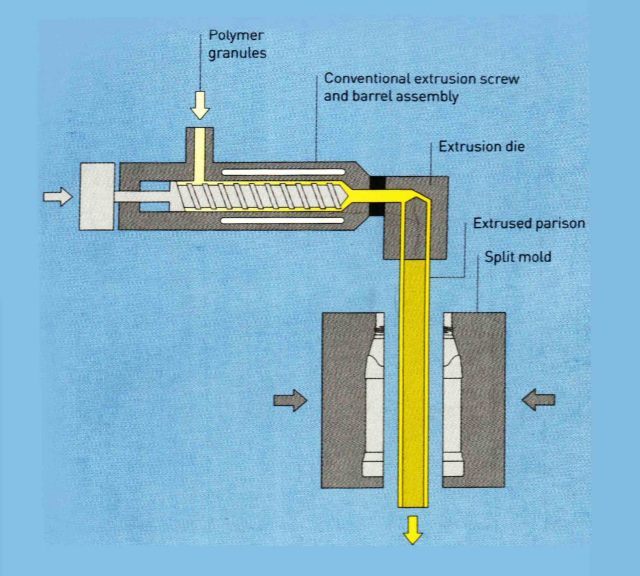

Direct extrusion blow molding. This method directly extrudes a parison from the extruder.

Its advantages include: simple structure of molding equipment and mold, less investment, low production cost of products, easy operation, suitable for thin-walled, complex-shaped, and irregular products, and suitable for blow molding of various plastics.

It is currently the basic molding method commonly adopted by small enterprises in our country. Its disadvantage is: since the extrusion speed of the parison is slow, a larger parison will sag due to its own weight, causing the parison wall to be uneven and produce internal stress, thereby leading to uneven thickness of the blow molded product.

Therefore, this method is suitable for the production of small containers. As for the problem of post-processing of plastic parts to remove flash, as the level of automation increases, manual operations to remove flash are decreasing, and product quality is getting higher.

Extrusion-storage-pressure blow molding. Its production process involves extruding the plastic melt into a storage cylinder. When the material in the storage cylinder reaches a certain amount, it is pressed out by a hydraulic cylinder in a measured and pressurized way, and a hollow container consistent with the shape of the mold cavity wall is obtained through the machine head.

The parisons produced by this process have the following advantages:

Firstly, using the storage device, larger containers can be produced with smaller equipment. For example, a medium 65 extruder can produce a 50L barrel.

Secondly, the plastic melt is rapidly pressed out by the pressure system, allowing for the required length of the parison to be obtained in a short time, greatly reducing the sagging phenomenon of the parison, thereby ensuring product wall thickness uniformity.

The disadvantages are: due to the addition of a storage and pressure system, the equipment structure is complex. The design and maintenance of the hydraulic system bring some difficulties to production, and the equipment investment is larger than direct extrusion blow molding process.

There is no way to remedy skincare products once they have been affected by high temperatures. Therefore, it is important to store skincare products in a place away from direct sunlight and at an appropriate temperature.

There is no way to remedy skincare products once they have been affected by high temperatures. Therefore, it is important to store skincare products in a place away from direct sunlight and at an appropriate temperature. Example scenarios:

Example scenarios:

The new laser technology can be applied to any robust-skinned food, including apples, avocados, apricots, bananas, grapefruit, kiwis, lemons, limes, oranges, pears, tangerines, papayas, peaches, persimmons, coconuts, figs, pomegranates, plums, lychees, mangoes, corn, chili peppers, cucumbers, ginger, garlic, onions, carrots, celery, tomatoes, pumpkins, zucchinis, artichokes, beets, Brussels sprouts, cabbage, eggplants, fennel, peas, potatoes, sweet potatoes, asparagus, radishes, turnips, and cauliflower.

The new laser technology can be applied to any robust-skinned food, including apples, avocados, apricots, bananas, grapefruit, kiwis, lemons, limes, oranges, pears, tangerines, papayas, peaches, persimmons, coconuts, figs, pomegranates, plums, lychees, mangoes, corn, chili peppers, cucumbers, ginger, garlic, onions, carrots, celery, tomatoes, pumpkins, zucchinis, artichokes, beets, Brussels sprouts, cabbage, eggplants, fennel, peas, potatoes, sweet potatoes, asparagus, radishes, turnips, and cauliflower.

And compared to most other types of packaging, airless packs have a high restitution rate—waste is avoided, as nearly all of the formula is used.

And compared to most other types of packaging, airless packs have a high restitution rate—waste is avoided, as nearly all of the formula is used.