What problems should be paid attention to when purchasing cosmetic packaging materials?

Almost all cosmetic manufacturers know that in addition to raw materials, cosmetic packaging materials are equally important. Packaging materials are not only containers, but also product promotion and product quality. Therefore, manufacturers must attach great importance to the purchase of packaging materials. What problems should be paid attention to when purchasing cosmetic packaging materials? Let’s look at it together.

1.Is the material “compatible”?

The “Cosmetics Safety Technical Specification 2015 Edition” stipulates that packaging materials that directly contact cosmetics should be safe, must not chemically react with cosmetics, and must not migrate or release toxic and harmful substances that are harmful to the human body. For example, heavy metals in metal packaging, plasticizers in plastic packaging bags, and bisphenol A and its derivatives dissolve into cosmetics that come into direct contact with it, threatening the quality of cosmetics and the human body. Therefore, it is necessary to carry out compatibility testing on the packaging to avoid unnecessary losses. 2. Does the printing quality pass? Cosmetic packaging requires exquisite printing and good visual beauty, so its printing quality inspection is particularly important. At present, the routine items of cosmetic packaging printing quality inspection mainly include the abrasion resistance of the printing ink layer (anti-scratch performance), ink adhesion fastness and color discrimination inspection. During the inspection process, the packaging products do not appear ink drop or deinking, etc. Qualified product.

2.Is the design reasonable? For companies, while considering the cost, they should also consider market expectations, and control the design of packaging materials, from container shape to label copywriting, from style positioning to transportation risks, from internal packaging to outsourcing, Wait, consider it all. Especially for the market characteristics and potential of the product, the basic situation of the consumer group, such as: the age of the consumer group, economic income, cultural quality and so on. If a good product does not have a suitable appearance, it will ultimately damage the overall image of the product.

3.Is the capacity standard? There are many types of skin care packaging materials and the process is more complicated. Sometimes it is inevitable that there will be a gap between the container capacity and the design standard. Therefore, before the production of the container, the characteristics of the material should be fully considered and controlled in a targeted manner. Whether the special specifications are complete, whether the appearance is beautiful, whether the vision is comfortable, etc. When negotiating business, many companies often only know that they are produced according to the model. In fact, this is incomplete, because the material body is different, and the net content of the same container is different.

4.Is the package temperature resistant? Some cosmetic inner packages are made of composite films, which use adhesives to bond films of different materials together, and different materials have different shrinkage rates, so when the temperature changes (regardless of Whether it is high temperature or low temperature), composite film bags will appear delamination and surface wrinkles. Therefore, the flexible packaging must be tested for temperature resistance.

5.Is the heat-sealing edge quality resistant? Heat sealing strength is one of the important indicators to measure the quality of packaging. Flexible packaging requires a certain degree of strength and tightness in the seal, and can withstand the pressure of a certain weight of filler to ensure that the packaging does not crack and leak during transportation. (1) Check the tightness. Use an ultrasonic sealing tester or use a vacuum method to observe the tightness of the heat-sealed edge of the flexible packaging bag. (2) Check the heat seal strength. When testing the heat-sealing strength, samples of the same width should be cut from the heat-sealed part of the flexible packaging bag in the vertical direction, and then the two ends of the strip-shaped sample should be fixed on the tension device and sent to the fixture for stretching, and the failure heat should be calculated. The maximum force value of the sealing part. It should be noted that in addition to the tensile strength of the blank packaging material, the influence of the contents on the heat-sealed part must also be considered. (3) Check the compressive strength.

The compressive strength of the flexible package can be tested using a press. Place the sample with the contents on the sample table, slowly press it to the required pressure, and hold it for 15 seconds. If there is no edge seal cracking, it is qualified. As for the amount of pressure to be applied, it depends on the situation. Different terminal enterprises and different products may have different requirements.

6.Is the package tearing smoothly? Most of the packaging bags of facial masks have wedge-shaped easy-to-tear openings. When consumers open the product, they must ensure that the opening process is smooth. It should be noted that during the tear test, the clamping force provided to the material must be large enough so that the material will not “slip” during the test. However, when consumers actually open the flexible packaging bag, if the force fit is not good, the “slip” phenomenon may occur when the grip is not strong enough, which may cause difficulty in opening. Therefore, in packaging design, packaging designers must comprehensively consider these properties of flexible packaging materials and find the best solution.

7.Is the copy standard? The country has very strict label management on cosmetics, and must be strictly implemented in accordance with the standards, especially for characteristic products. Some ingredients and their indicators must not have the slightest error or discrepancy. Otherwise, no matter how good the packaging materials are, they cannot be used. In addition, in terms of the efficacy of the product, we must carefully scrutinize and review it carefully to avoid false content, avoid banned words, and avoid consumer ambiguity.

8. Does the proportion of defective products exceed the standard? Cosmetic packaging materials, especially outsourcing materials, are often produced manually, such as cartons, handbags, etc., due to the low degree of automation, inevitably defective or defective products will appear. Some machine-produced glass bottles, hoses, etc., will have problems of one kind or another in terms of color difference, missing print, shape, etc. Therefore, these problems must be considered when purchasing. If the ratio of qualified products to defective products does not exceed the basic standard during the package material inspection, then the packaging material purchase is successful, but when ordering packaging materials, the quantity should be increased appropriately to ensure that it is sufficient and there is room for selection.

Canvard Packaging International Co.,Ltd was founded in 2011. It is an enterprise with a factory in Guangzhou. It is a company specializing in the production of plastic bottle, plastic jar, plastic container, airless dispenser bottle, foam pump bottle, deodorant stick tube, PET bottle, Professional company of detergent bottle, ampoule bottle and other cosmetic packaging materials.

Welcome to contact us to share your ideas. Thank you

Welcome to share your comment

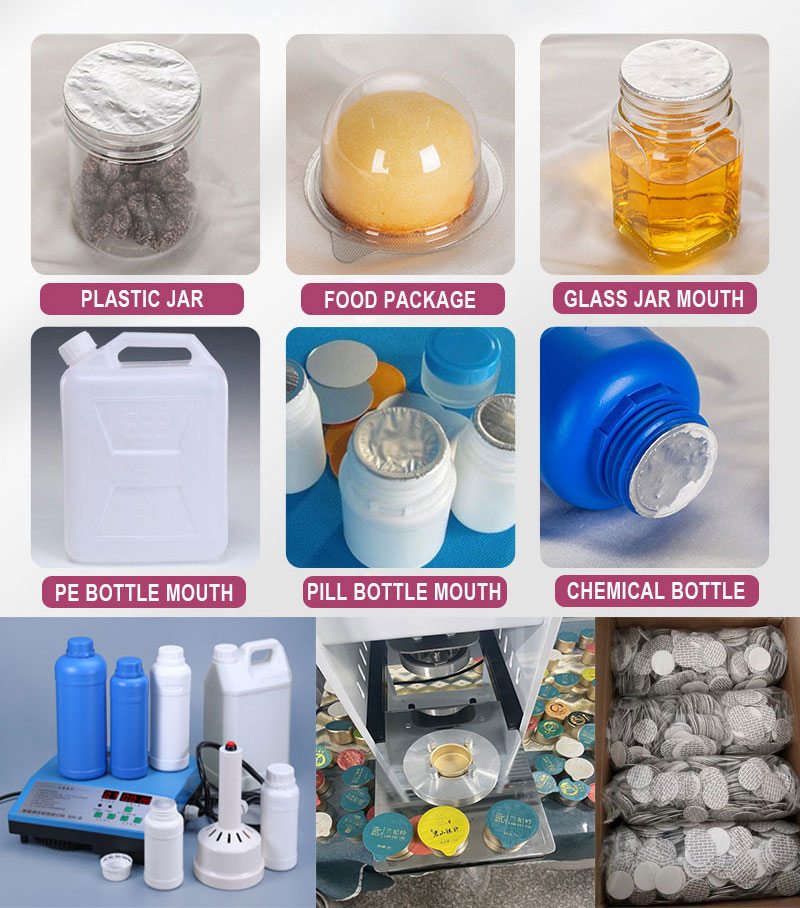

Seal foil is widely used in PET, PE, PP, PVC, PS, ABS, metal, aluminum and glass bottles containers.

Seal foil is widely used in PET, PE, PP, PVC, PS, ABS, metal, aluminum and glass bottles containers. Machines required for pressure-sensitive foil sealing gasket:

Machines required for pressure-sensitive foil sealing gasket:

Electromagnetic induction aluminum foil sealing machine is widely used in the sealing of containers of medicines, liquid medicines, spices, detergents, milk, beverages, food, chemical products, etc., and plays the role of sealing, anti-counterfeiting and anti-theft. The equipment uses the principle of electromagnetic induction to instantly generate high temperature on the aluminum foil on the bottle mouth, and then fuse the aluminum foil on the bottle mouth to achieve the function of sealing. It has good moisture-proof, mildew-proof and anti-counterfeiting effects, thereby prolonging the storage time of items.

Electromagnetic induction aluminum foil sealing machine is widely used in the sealing of containers of medicines, liquid medicines, spices, detergents, milk, beverages, food, chemical products, etc., and plays the role of sealing, anti-counterfeiting and anti-theft. The equipment uses the principle of electromagnetic induction to instantly generate high temperature on the aluminum foil on the bottle mouth, and then fuse the aluminum foil on the bottle mouth to achieve the function of sealing. It has good moisture-proof, mildew-proof and anti-counterfeiting effects, thereby prolonging the storage time of items. 2, Principle.

2, Principle.

.jpg)

.jpg) On November 29, the newly-built Guangzhou Nansha Port Railway completed the replacement of the main line with long track, laying a solid foundation to ensure the opening of freight at the end of the year and the subsequent passenger transport conditions.

On November 29, the newly-built Guangzhou Nansha Port Railway completed the replacement of the main line with long track, laying a solid foundation to ensure the opening of freight at the end of the year and the subsequent passenger transport conditions.